Purge plugs play a vital role in TIG welding by protecting welds from contamination. They help create a clean, oxygen-free space inside pipes during welding.

These plugs seal pipe ends tightly to allow inert gas to flow inside. This gas protects the weld area from air and moisture, preventing weak spots and corrosion. Made from high-temperature silicone, purge plugs resist heat and fit various pipe sizes.

Kits include multiple plugs and fittings for different welding needs. Using purge plugs improves weld quality and strength, especially in stainless steel and alloy pipes. Choosing the right size and type ensures proper sealing and gas flow. For fabricators working on exhausts, headers, or manifolds, purge plugs help achieve smooth, clean welds every time. They are simple tools that make a big difference in TIG welding results.

3mirrors Silicone Purge Plugs Welding Back Purging Plugs Kit

The 3mirrors Silicone Purge Plugs Welding Back Purging Plugs Kit is ideal for professional welders and metal fabricators who require precise and clean welding results. Those working with stainless steel, titanium, or other reactive metals will benefit from this kit, as it helps prevent oxidation and contamination during welding by providing an effective back purging solution. It is also suitable for both industrial and workshop environments where maintaining weld quality is critical.

Pros:

- Includes a variety of sizes ranging from 0.9 inch to 4.0 inch to accommodate different pipe diameters.

- Made of durable silicone material that ensures a tight seal and withstands high temperatures.

- Comes with fitting sleeves that enhance the stability and effectiveness of the purge plugs during welding.

- Kit contains 14 plugs, providing ample quantity for multiple projects or replacements.

- Reusable and easy to clean, offering long-term cost efficiency.

Cons:

- May not fit pipes or tubes outside the specified size range of 0.9 inch to 4.0 inch.

- Some users might find the setup process requires initial practice to achieve a perfect seal.

The 3mirrors Silicone Purge Plugs Kit is designed with versatility and durability in mind. Its range of plug sizes ensures compatibility with a wide array of pipe diameters, making it a flexible tool for various welding jobs. The high-quality silicone construction offers excellent resistance to heat and deformation, which is essential for maintaining a secure purge environment during the welding process. This feature helps reduce weld defects and improves the overall integrity of the joint.

Additionally, the inclusion of fitting sleeves enhances the plugs’ sealing capabilities, ensuring that the inert gas used for purging does not escape and that the weld area remains uncontaminated. This results in cleaner welds with superior corrosion resistance and mechanical properties. The kit’s reusability and ease of cleaning make it a cost-effective choice for professionals who frequently perform back purging in their welding operations.

To buy this product, click here.

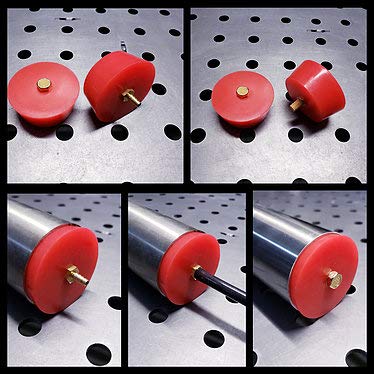

High Temperature Silicone Welding Back Purging Plugs Complete Kit

The Strictly Modified High Temperature Silicone Welding Back Purging Plugs Complete Kit 1.25″-4″ (Set of 12) is ideal for professional welders and fabrication specialists who require durable and reliable tools for high-temperature welding applications. If you are involved in industries such as pipeline construction, HVAC, or metal fabrication where precise back purging is essential, this kit is designed to enhance your workflow and ensure superior welding quality.

Pros:

- Made from high temperature silicone for excellent heat resistance

- Comes as a complete set of 12 plugs covering sizes from 1.25″ to 4″

- Durable and reusable for extended use on multiple projects

- Bright red color for easy visibility during welding operations

- Designed and manufactured by Strictly Modified, ensuring quality and reliability

Cons:

- May be slightly costly for hobbyists or occasional users

- Limited to specific pipe sizes (1.25″-4″), requiring additional kits for other sizes

This kit features a range of silicone welding back purging plugs that are engineered to withstand extreme temperatures encountered during welding processes. The high temperature silicone material not only provides excellent thermal resistance but also maintains flexibility, allowing for a secure fit in various pipe diameters within the specified range. This adaptability reduces the need for multiple types of plugs and ensures a consistent purging environment to prevent weld contamination.

Users will benefit from the comprehensive size range included in the set, which covers common pipe sizes from 1.25″ to 4″. The plugs’ bright red color enhances visibility, reducing the chance of misplacement or oversight during complex welding tasks. Additionally, the durability and reusability of these plugs help to lower overall project costs while maintaining high welding standards. Manufactured by Strictly Modified, this kit guarantees quality control and dependable performance in demanding work conditions.

To buy this product, click here.

Strictly Modified High Temp Silicone Welding Back Purging Plugs

The Strictly Modified High Temp Silicone Welding Back Purging Plugs 3″ – 3.25″ (Set of 2) are perfect for professional welders and hobbyists who require precision and quality in their welding projects. These plugs are designed for those who often work with stainless steel or titanium piping and need to ensure a clean, efficient purging process.

Pros:

- Made from high-quality silicone that withstands high temperatures.

- Easy to install and remove, saving time during setup.

- Versatile size fits pipes from 3″ to 3.25″.

- Durable and reusable, providing long-term value.

- Bright green color for easy visibility.

Cons:

- May not fit pipes smaller than 3 inches or larger than 3.25 inches.

- Initial cost might be higher compared to basic plugs.

- Limited color options available.

These silicone welding plugs are crafted to endure the intense conditions often encountered during welding. Their high-temp resistance ensures that they won’t degrade or fail under high heat, making them reliable for back purging in critical applications. The green color not only helps in quick identification but also adds an element of safety, preventing accidental misplacement or loss.

Moreover, the versatile size of these plugs allows them to adapt to slightly varying pipe diameters, offering flexibility and convenience to the user. The durability of the silicone material means they can be reused multiple times without degradation, offering excellent value over time. Despite their slightly higher upfront cost, the long-term savings and enhanced performance make these plugs a wise investment for any serious welder.

To buy this product, click here.

Strictly Modified High Temperature Silicone Welding Back Purging Plugs

The Strictly Modified High Temperature Silicone Welding Back Purging Plugs 2″ – 2 1/4″ (Set of 2) are ideal for professional welders and metal fabricators who require precise and reliable back purging solutions during high-temperature welding processes. If you need durable, heat-resistant plugs to ensure clean welds and protect weld integrity, this product is designed specifically for you.

Pros:

- Made from high-temperature resistant silicone for durability under extreme conditions

- Provides an effective seal for back purging to prevent oxidation and contamination

- Comes as a set of 2 in convenient sizes (2″ – 2 1/4″) suitable for various pipe diameters

- Available in blue or purple colors for easy identification on the job site

- Manufactured by Strictly Modified, a trusted brand known for quality welding accessories

Cons:

- Limited to pipe sizes between 2″ and 2 1/4″, which may not fit larger or smaller applications

- Silicone material may require careful handling to avoid tearing if over-stretched

The Strictly Modified High Temperature Silicone Welding Back Purging Plugs excel in providing a reliable seal during welding processes where back purging is critical. The use of premium silicone material ensures these plugs withstand the intense heat generated during welding, maintaining their form and functionality without degrading. This feature is essential for welders who aim to achieve contamination-free welds by preventing atmospheric gases from affecting the weld pool.

Additionally, the availability of these plugs in two standard sizes allows for versatility across a range of pipe diameters, making them a practical choice for professionals working with different setups. The vibrant blue or purple colors not only aid in quick identification but also add to the ease of use on busy job sites. Overall, these back purging plugs offer a combination of durability, convenience, and efficiency, making them a valuable tool for ensuring high-quality welding outcomes.

To buy this product, click here.

High Temperature Silicone Welding Back Purging Plugs

Ideal for professional welders and metal fabricators, the Strictly Modified High Temperature Silicone Welding Back Purging Plugs 2.5″ Set of 2 is designed for those seeking reliable and efficient tools to enhance welding quality. If you frequently work with stainless steel or other sensitive metals requiring precise back purging, this product is tailored to meet your high-performance needs.

Pros:

- Made from high temperature silicone ensuring durability and heat resistance

- Effective back purging for clean, contamination-free welds

- Reusable and easy to install and remove

- Bright red color for quick visibility on the job

- Comes in a set of 2 for convenience and value

Cons:

- Limited to 2.5″ size, which may not fit all pipe diameters

- Silicone material may wear out faster under extremely harsh conditions

The Strictly Modified High Temperature Silicone Welding Back Purging Plugs are crafted with precision to withstand the intense heat generated during welding processes. Their silicone construction offers excellent thermal stability, which protects the plug from melting or deforming, ensuring consistent performance throughout the project. This feature benefits users by reducing downtime caused by replacing damaged plugs and guarantees a reliable seal for optimal back purging results.

In addition to durability, these plugs provide an effective seal that prevents atmospheric contamination of the weld area, leading to stronger, cleaner welds. Their bright red color enhances visibility, making it easier for welders to position and monitor the plugs during use. Overall, this set of two plugs offers a practical and cost-effective solution for professionals aiming to improve weld quality and efficiency.

To buy this product, click here.

Silicone Back Purge Plugs For Welding

The Silicone Back Purge Plugs for Welding by Ticon Industries are ideal for professional welders and fabricators who require precise and clean welds, especially when working with stainless steel and other alloys that need a controlled atmosphere. If you perform TIG welding and need to protect the backside of the weld from oxidation, these Silicone Trailing Shields are a perfect choice to ensure high-quality results.

Pros:

- Made from durable silicone material that withstands high temperatures.

- Compact dimensions (6.0 inches height, 3.0 inches width, 1.0 inch length) ensure easy handling and placement.

- Reusable and easy to clean, offering long-term cost savings.

- Provides excellent back purge protection to prevent oxidation and contamination during welding.

Cons:

- May require some practice to fit properly on different pipe sizes.

- Limited to specific welding applications like TIG, less versatile for other welding types.

The Silicone Back Purge Plugs are designed with precision to offer effective sealing during the welding process, which is crucial for maintaining weld integrity. The silicone construction provides excellent heat resistance, allowing the plugs to endure the high temperatures associated with welding without deforming or breaking down. This ensures that welders can rely on consistent performance even during extended use.

Additionally, the compact size and lightweight design make these plugs easy to handle and position, which can significantly reduce setup time. Their reusable nature not only makes them environmentally friendly but also cost-effective in the long run. By effectively purging the backside of welds, these plugs help create cleaner, stronger welds with reduced risk of defects, benefiting both professional welders and hobbyists who demand precision in their work.

To buy this product, click here.

Quick Disconnect Tig Welding Back Purge Hose Kit

The Strictly Modified Quick Disconnect Tig Welding Back Purge Hose Kit (10 ft Length) is ideal for professional welders and metal fabrication enthusiasts who require precise control over the welding environment. If you need a reliable and efficient solution for back purging during TIG welding to ensure clean and high-quality welds, this hose kit is designed specifically for your needs.

Pros:

- Quick disconnect feature for easy and fast setup and removal

- Durable 10 ft length offers flexibility and convenience during welding tasks

- High-quality construction from the trusted Strictly Modified brand ensures long-lasting performance

- Black color adds a sleek and professional look while being easy to maintain

Cons:

- May be slightly heavier compared to shorter hose kits due to its length

- Specific to TIG welding applications, limiting versatility for other welding types

The Strictly Modified Quick Disconnect Tig Welding Back Purge Hose Kit is engineered to provide welders with a seamless experience when creating back purges during TIG welding. The quick disconnect mechanism significantly reduces setup time, allowing welders to focus more on their craft rather than equipment adjustments. The 10-foot length offers ample reach without compromising on control, making it perfect for a range of welding projects from small repairs to larger fabrications.

Constructed with durability in mind, this hose kit withstands the rigors of frequent use in demanding workshop environments. Its compatibility with standard TIG welding back purge systems ensures that it integrates effortlessly with existing setups, providing a steady and controlled flow of purge gas to improve weld quality. Overall, the Strictly Modified hose kit enhances welding precision, reduces contamination risks, and supports professional-grade results.

To buy this product, click here.

Tig Welding Back Purge Plug Kit For 2.5″ Inch Pipe

The TIG WELDING BACK PURGE PLUG Kit for 2.5″ INCH PIPE (heat wear resistant) is ideal for professional welders and metal fabricators who require precise and clean welds on stainless steel and other reactive metals. This kit is perfect for those working on pipe welding projects where controlling oxidation and contamination is crucial. If you need a reliable tool to maintain high-quality welds in industrial or workshop settings, this product is designed for you.

Pros:

- Made from heat wear resistant materials ensuring durability during high-temperature welding processes.

- Specifically designed for 2.5-inch pipes, providing a perfect fit and secure sealing.

- Helps achieve cleaner welds by effectively purging oxygen from the backside of the weld area.

- Produced by TJC industries, a trusted manufacturer in welding accessories.

- Generic brand offering an affordable solution without compromising quality.

Cons:

- Limited to use with 2.5-inch pipes, which may not suit other pipe sizes.

- May require additional equipment or expertise to operate effectively during the welding process.

The TIG WELDING BACK PURGE PLUG Kit features a robust construction designed to withstand the intense heat generated during TIG welding. Its heat wear resistant properties allow it to maintain integrity even after prolonged exposure to high temperatures, reducing the risk of damage and downtime. This ensures that welders can rely on the tool for consistent performance across multiple projects. The kit’s design provides an airtight seal on 2.5-inch pipes, which is essential for maintaining an inert atmosphere and preventing oxidation on the backside of the weld. This results in stronger, cleaner, and more professional welds.

Using this back purge plug kit offers significant benefits, including improved weld quality and reduced post-weld cleaning time. By effectively purging oxygen, it minimizes the formation of weld defects such as porosity and discoloration. This not only enhances the aesthetic appeal of the weld but also contributes to the structural integrity of the joint. Additionally, the plug’s compatibility with standard pipe sizes and its durable build make it a practical investment for welders aiming to increase efficiency and achieve superior results in their work.

To buy this product, click here.

3mirrors Silicone Purge Plugs Set Of 4

The 3mirrors 5.0″-6.0″ Non-toxic and High Temperature Silicone Purge Plugs are ideal for professional welders and fabricators who work on header, manifold, and exhaust fabrication. If you need reliable and durable purging plugs that can withstand high temperatures without releasing toxins, this set is perfect for ensuring clean welds and improved joint quality.

Pros:

- High temperature resistance suitable for demanding welding applications

- Made from non-toxic silicone ensuring safety during use

- Comes in a set of 4 for multiple uses or different pipe sizes

- Lightweight at 4.4 pounds, easy to handle and position

- Flexible size range from 5.0″ to 6.0″ fits various pipe diameters

Cons:

- Limited to pipe diameters between 5.0″ and 6.0″, not suitable for smaller or larger pipes

- May require occasional cleaning to maintain optimal performance

The 3mirrors purge plugs feature a robust silicone construction that can tolerate the intense heat generated during welding without degrading or emitting harmful substances. This ensures that your workspace remains safe and that the plugs maintain their integrity throughout the welding process. The non-toxic nature of the silicone also means you don’t have to worry about contaminating the weld area or exposing yourself to dangerous fumes.

Designed specifically for header, manifold, and exhaust fabrication, these plugs provide a tight seal inside pipes, enabling effective back purging and preventing oxidation during welding. The flexibility and durability of the silicone material allow for easy installation and removal, saving you time and effort on the job. Overall, these purge plugs enhance weld quality by maintaining a controlled atmosphere inside the pipe, leading to stronger and cleaner welds.

To buy this product, click here.

Modified Welding Back Purge Plug 4″ Pipe & Tube

The Strictly Modified Welding Back Purge Plug 4″ Pipe & Tube (Single Plug) is ideal for professional welders and metal fabrication specialists who require precise and effective back purging during welding projects. This product is perfect for those working with 4-inch diameter pipes and tubes, aiming to achieve clean, high-quality welds by preventing oxidation and contamination in the weld area.

Pros:

- Durable Construction ensures long-lasting use in demanding welding environments.

- Compact Dimensions (4.0″ height and width, 2.25″ length) make it easy to handle and fit in tight spaces.

- Lightweight Design at just 1.6 pounds for convenient portability.

- Effective Back Purging enhances weld quality by minimizing oxidation.

- Brand Reliability from Strictly Modified, known for quality welding accessories.

Cons:

- Designed specifically for 4″ pipes and tubes, limiting versatility for other sizes.

- Single plug packaging may require purchasing multiple units for larger projects.

The Strictly Modified Welding Back Purge Plug is engineered to provide an airtight seal inside 4-inch pipes and tubes, allowing welders to back purge with inert gas effectively. This process eliminates oxygen from the weld zone, reducing the risk of oxidation and resulting in cleaner, stronger welds. Its compact and lightweight design makes it practical for both shop and field use, ensuring ease of installation and removal.

Constructed with durable materials, this plug withstands the rigors of industrial welding environments while maintaining a reliable seal. The precise fit and robust build contribute to consistent weld quality, which is critical for applications in industries such as aerospace, automotive, and plumbing. Overall, this tool supports welders in achieving professional-grade results with increased efficiency and reduced post-weld cleanup.

To buy this product, click here.

Frequently Asked Questions

What Are Purge Plugs Used For In Tig Welding?

Purge plugs seal pipe ends to create an inert gas environment inside. This prevents oxidation during TIG welding. They ensure clean, high-quality welds on stainless steel and other metals. Using purge plugs improves weld integrity and appearance by controlling back purging effectively.

How Do Silicone Purge Plugs Benefit Welding?

Silicone purge plugs withstand high temperatures and provide excellent sealing. Their flexibility fits various pipe sizes, ensuring gas tightness. They resist heat damage, making them ideal for TIG welding. Silicone plugs improve weld quality by maintaining consistent inert gas coverage inside the weld area.

What Sizes Do 3mirrors Silicone Purge Plugs Come In?

3mirrors silicone purge plugs come in sizes from 0. 9 inch up to 6. 0 inches. Kits include multiple plugs and fitting sleeves for different pipe diameters. This range covers most common TIG welding applications on pipes, headers, and exhaust fabrications.

Can Purge Plugs Be Reused For Multiple Welds?

Yes, many silicone purge plugs are reusable if cleaned properly after use. Their durable, heat-resistant material allows multiple uses without losing sealing effectiveness. Proper care extends their lifespan and ensures consistent welding quality over time.

Why Is Back Purging Important In Tig Welding?

Back purging protects the weld’s backside by supplying inert gas like argon. This prevents oxidation and contamination during welding. It is critical for welding stainless steel or other reactive metals. Using back purge plugs and kits ensures a clean, strong weld joint.

What Features Does The Strictly Modified Purge Plug Kit Offer?

Strictly Modified kits include high-temperature resistant silicone plugs with quick disconnect fittings. They cover sizes from 1. 25″ to 4″ and provide secure seals for TIG welding. These kits improve efficiency and weld quality by simplifying back purging setup and gas control.

Conclusion

Choosing the right purge plugs makes TIG welding cleaner and easier. These silicone plugs fit many pipe sizes and resist high heat well. They help prevent oxidation inside the weld area, improving weld quality. Using a complete kit ensures you have the right size for any project.

Quick disconnect hose kits add convenience and save time during setup. Whether working on exhaust systems, headers, or manifold fabrication, these plugs provide a reliable seal. They also reduce gas waste and keep the weld zone protected. For both beginners and experienced welders, investing in quality purge plugs improves results.

Simple to use and reusable, they are a practical tool for TIG welding tasks. Remember, clean and well-purged welds mean stronger joints and less rework. Good purge plugs are a small step that makes a big difference in your welding projects.

About The Author

Jeff Grill

administrator

Hi, I’m Jeff Grill — a certified welding expert and instructor based in Long Island, NY.

With over three decades in the industry, I’m passionate about combining theoretical knowledge with hands-on experience to train the next generation of skilled welders.

I specialize in all forms of arc welding, including GMAW, GTAW, GMAW, FCAW & SAW. But my experience isn’t limited to just those—I’m also knowledgeable in oxyfuel gas welding and plasma arc cutting.

My years as a welding inspector and supervisor have honed my ability to ensure the highest standards in welding quality and safety, making me adept at executing and overseeing complex welding operations.