Are you struggling to get perfect welds with your stick welding? One simple detail could be holding you back: the proper arc length.

Knowing the right arc length can make a huge difference in the strength, appearance, and quality of your welds. But what exactly is the proper arc length for stick welding, and how can you control it every time you strike an arc?

Keep reading, because mastering this key skill will improve your welding results and save you time and materials. Let’s dive into what you need to know to get it right.

Stick Welding Basics

Stick welding, also known as Shielded Metal Arc Welding (SMAW), is a popular technique for joining metals using a consumable electrode. Understanding the basics of stick welding sets a solid foundation for mastering the proper arc length, which is crucial for producing strong, clean welds. If you’ve ever struggled with inconsistent welds or excessive spatter, revisiting the fundamentals might reveal what you’re missing.

Key Components

Stick welding involves a few essential parts that work together to create the weld. The electrode, or welding rod, melts and fuses the metals. It’s covered with flux, which generates shielding gas to protect the weld from contamination.

You also have the welding machine that provides the electrical current necessary to create the arc. The workpiece, the metal you’re welding, completes the circuit. Each component plays a vital role in the quality of your weld.

Role Of Arc Length

The arc length is the distance between the tip of the electrode and the surface of the workpiece. Maintaining the correct arc length is critical. Too short, and the electrode might stick to the metal; too long, and the arc becomes unstable, causing poor penetration and excessive spatter.

Typically, the proper arc length matches the diameter of the electrode. For example, if you’re using a 3/32 inch rod, your arc length should be about 3/32 inch. Have you noticed how a slight change in this distance affects your weld bead’s appearance and strength? Paying attention to arc length can transform your stick welding results dramatically.

Credit: unimig.com.au

Ideal Arc Length Range

Maintaining the proper arc length is key to good stick welding. The ideal arc length ensures strong welds and steady performance. Too short or too long arc lengths can cause defects and weak joints. Knowing the right range helps create clean and reliable welds.

Recommended Measurements

The ideal arc length usually matches the diameter of the electrode. For example, a 1/8-inch electrode needs about a 1/8-inch arc length. This measurement keeps the arc stable and heat balanced. A general rule is to keep the arc length between 1/8 inch and 1/4 inch.

Keeping the arc length consistent helps prevent common issues like:

- Excessive spatter

- Poor penetration

- Unstable arc

Factors Influencing Arc Length

Several factors affect the best arc length for your welding task. These include:

- Electrode type:Different rods need different arc lengths.

- Welding position:Vertical or overhead welding may require shorter arcs.

- Current settings:Higher currents can support longer arcs.

- Material thickness:Thicker metals often need more heat and longer arcs.

Adjust arc length to fit these factors for better weld quality and fewer defects.

Effects Of Incorrect Arc Length

Understanding the proper arc length in stick welding is crucial for achieving optimal weld quality. Incorrect arc length can lead to a series of issues that may affect the durability and appearance of your welds. By mastering the arc length, you can improve both your welding skills and the final product. Let’s explore the effects of having an arc length that is too short or too long.

Too Short Arc Length

When the arc length is too short, it can result in excessive spatter and a rough, uneven weld bead. This happens because the arc struggles to maintain stability, leading to inconsistent heat distribution.

You may notice the electrode sticking to the workpiece frequently, which interrupts your workflow and can be frustrating. Moreover, a short arc often causes insufficient penetration, compromising the strength of the weld.

Consider whether you’ve experienced these issues before. Could adjusting the arc length have improved your results?

Too Long Arc Length

On the flip side, a too-long arc length can lead to a different set of problems. It often results in a weak, porous weld due to the increased exposure to atmospheric gases.

The weld bead may appear overly wide and flat, lacking the necessary depth for strength. This is because the heat dissipates quickly, preventing proper fusion between the electrode and workpiece.

Have you ever noticed a lackluster finish in your welds? Could this be the reason behind it?

By understanding these effects, you can make informed adjustments to your arc length, ensuring your welding is both efficient and effective. Remember, the key lies in finding the perfect balance to avoid these common pitfalls.

Techniques To Maintain Proper Arc Length

Maintaining the proper arc length during stick welding is key to producing clean, strong welds. The right distance between your electrode and the workpiece affects the weld’s penetration and bead appearance. If you hold the arc too long or too short, it can lead to spatter, weak joints, or even porosity.

Mastering techniques to keep the arc length steady can improve your weld quality significantly. Here are some practical ways you can control and maintain that critical gap.

Hand Positioning Tips

Your hand position plays a big role in controlling the arc length. Keep your wrist steady and use your fingers to lightly grip the electrode holder—avoid a tight, rigid grip that tires your hand quickly.

Try resting your forearm on the work surface or a stable object to reduce shaking. Small, deliberate movements help you maintain a consistent distance without sudden jumps.

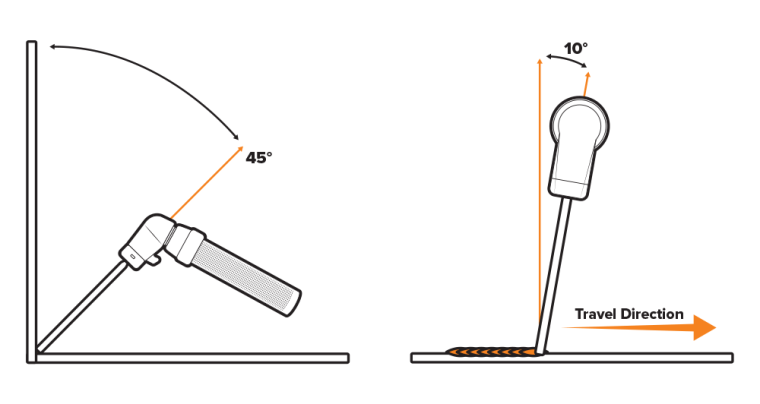

Practice holding the electrode at a slight angle, around 10-15 degrees from vertical, to give yourself better visibility and control. Have you noticed how your hand naturally adjusts when you focus on a steady arc? That awareness is a skill you can sharpen with time.

Using Visual And Audio Cues

Both your eyes and ears provide valuable feedback when welding. Watch the arc’s brightness and size closely—if it flickers or grows too long, you need to adjust. A short arc often produces a sharp, bright spot with less spatter.

Listen carefully to the sound of your arc. A steady, buzzing noise usually means the arc length is just right. If you hear popping or crackling, it may indicate the arc is too long or too short.

Try practicing in a quiet space to train your ears. Can you distinguish the difference in arc sounds as you change the distance? This sensory connection helps you correct your technique quickly during real welding jobs.

Adjusting Arc Length For Different Materials

Adjusting the arc length is key to good stick welding results. Different metals need different arc lengths for proper fusion and strong welds. Too long or too short an arc can cause defects, poor penetration, or excessive spatter. Knowing how to change the arc length helps you weld each material correctly.

Welding Mild Steel

Mild steel requires a steady and controlled arc length. Keep the arc length about equal to the diameter of the electrode. This balance helps maintain a stable arc and smooth weld bead.

Too long an arc creates more spatter and weak welds. Too short an arc causes the rod to stick and uneven beads. Adjust the arc length slightly if welding thin or thick mild steel to get the best results.

Working With Stainless Steel And Aluminum

Stainless steel needs a shorter arc length than mild steel. Keep the arc length slightly less than the electrode diameter. This prevents overheating and warping the metal.

Aluminum requires careful control of the arc length. Use a shorter arc to avoid burning through the metal. A stable, short arc helps produce clean and strong welds on aluminum surfaces.

Both metals are sensitive to heat. Adjust the arc length to control heat input and avoid defects like cracks and porosity.

Credit: yeswelder.com

Common Mistakes And How To Avoid Them

Maintaining the proper arc length during stick welding is crucial for a strong weld. Many welders make common mistakes that affect weld quality. Avoiding these errors helps achieve consistent, clean welds. Understanding these mistakes improves your welding skills and saves material.

Overextending The Arc

Holding the arc too far from the workpiece causes poor welds. The arc becomes unstable and weak. This leads to excessive spatter and weak penetration. The weld bead can look rough and uneven. Keep the arc length short and steady. A good rule is to hold the arc about the diameter of the electrode away. This helps maintain a stable arc and good weld fusion.

Inconsistent Arc Length

Changing the arc length during welding causes uneven heat. This results in irregular weld beads and weak spots. Too short an arc can stick the electrode to the metal. Too long an arc causes an unstable arc and porosity. Keep the arc length consistent throughout the weld. Practice steady hand movement and focus on the distance. This creates clean, strong welds with uniform appearance.

Tools To Help Control Arc Length

Controlling the arc length is crucial in stick welding to ensure a strong, clean weld. Using the right tools can make this task easier and more precise. These tools help maintain consistency and reduce mistakes, especially if you’re new to welding or working on detailed projects.

Welding Rod Holders

Welding rod holders are designed to give you a better grip and control over the electrode. They help keep the rod steady, which is essential for maintaining a consistent arc length. When your hand is stable, you avoid sudden movements that can cause the arc to lengthen or shorten unexpectedly.

Some rod holders come with ergonomic designs, reducing hand fatigue during long welding sessions. This comfort lets you focus more on your technique rather than struggling with the equipment. Have you noticed how a simple change in your grip can improve your weld quality?

Arc Length Gauges

Arc length gauges are tools made specifically to measure the distance between the electrode and the workpiece. Using one ensures you never guess the arc length, which is critical for producing uniform welds. They often come in simple shapes that fit right onto the electrode or welding rod.

With an arc length gauge, you can quickly check your setup before striking the arc. This small step saves time and reduces the risk of defects like excessive spatter or weak welds. Wouldn’t you agree that having a quick measurement tool at hand can boost your confidence and efficiency?

Credit: www.facebook.com

Frequently Asked Questions

What Is The Ideal Arc Length For Stick Welding?

The ideal arc length for stick welding is about equal to the diameter of the electrode. This ensures a stable arc and proper weld penetration.

How Does Arc Length Affect Weld Quality?

Short arc length produces smooth welds with less spatter. Long arc length causes excessive spatter and weak welds. Maintaining correct length improves weld strength.

Why Is Controlling Arc Length Important In Stick Welding?

Controlling arc length prevents defects like porosity and slag inclusion. It ensures consistent heat input and better weld bead appearance.

Can Improper Arc Length Damage Welding Equipment?

Yes, improper arc length can cause electrode sticking and damage the welding machine. Maintaining correct arc length protects both equipment and weld quality.

Conclusion

The right arc length makes stick welding easier and better. Too long or too short can cause poor welds. Keep the arc steady and close to the metal. This helps prevent defects like spatter or weak joints. Practice to feel the correct distance.

Good arc control saves time and materials. Remember, simple steps lead to strong, clean welds every time. Stick welding works best with the proper arc length.

About The Author

Jeff Grill

administrator

Hi, I’m Jeff Grill — a certified welding expert and instructor based in Long Island, NY.

With over three decades in the industry, I’m passionate about combining theoretical knowledge with hands-on experience to train the next generation of skilled welders.

I specialize in all forms of arc welding, including GMAW, GTAW, GMAW, FCAW & SAW. But my experience isn’t limited to just those—I’m also knowledgeable in oxyfuel gas welding and plasma arc cutting.

My years as a welding inspector and supervisor have honed my ability to ensure the highest standards in welding quality and safety, making me adept at executing and overseeing complex welding operations.